10 Essential Components For a Safer Working Environment

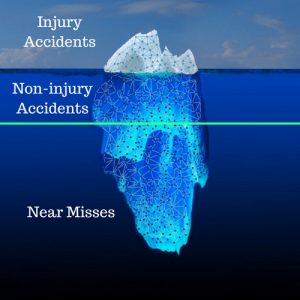

A safe working environment is a condition or state, it is not necessarily an event like an incident of an accident. This means that the low number of incidents or accidents doesn’t mean that the workplace is particularly safe. What really counts is the process of safety because it is an integral part of everyday activities in the workplace.

A safe working environment is a condition or state, it is not necessarily an event like an incident of an accident. This means that the low number of incidents or accidents doesn’t mean that the workplace is particularly safe. What really counts is the process of safety because it is an integral part of everyday activities in the workplace.

10 Essential Components for a Safer Working Environment

- Daily safety briefings. Every morning at the beginning of the work day or the shift, the leader holds an interactive safety briefing with his or her team. It lasts less than 10 minutes and has contributions from the team members.

Check out the toolbox talks I have for sale on Amazon here

- Weekly inspections to identify unsafe conditions. Every staff member participates in turn and conducts a regular safety inspection where they look for hazards and unsafe conditions. This can occur weekly or twice a week.

- Weekly inspections to identify unsafe behavior. Each week two staff members carry out a regular inspection where they are identifying unsafe behavior. The objective is to identify the unsafe behavior and mention it at the next daily safety briefing. Of course, no names are mentioned.

Check Out: How to Develop an Internal Safety Audit Schedule

- Accident and incident investigation. Every accident or near accident is investigated with the sole objective of prevention in the future. The process of investigation is not a witch hunt to apportion blame.

Want to learn more about Incident Investigations? Check out what I have available here.

- Constant improvement. During the daily safety briefings, the group members have an opportunity to recommend and discuss improvements to the workplace and the processes that are carried out within it

- Reporting near miss. Every single near miss (this is an incident where no damage or injury occurs) is investigated and prevention measures are put in place, so it will not happen again.

Check Out: Near Miss Policy

- Positive reinforcement. Each day the leader goes into the workplace and gives positive reinforcement to those members of staff for working safely. This encouragement and enthusiasm for safety is a great motivator for safe working practices.

- Blame. It is noticeable that all safe working environments do not use blame or punishment as tools for creating safe behavior. Instead, they use positive reinforcement, encouragement and recognition.

- Practical on-the-job training. Group members are continually receiving on-the-job training from experts within the company and outside.

- Effective leadership. It is no coincidence that all safe workplace environments have good leadership. This means that the leader is prepared to listen and has the skills to create followers. These leaders engender cooperation and most of all discretionary effort. They are the main reason why people are working safely. They are not invisible and spend between 30 and 50% of their time with their team members.

This Basic Emergency Response Plan template is useful for small businesses that want an emergency response plan, when it is only required to have a verbal plan. Having a written plan over a verbal plan provides additional safeguards, so all employees know the same responses to emergencies, and it can be referenced during an actual emergency.

This Basic Emergency Response Plan template is useful for small businesses that want an emergency response plan, when it is only required to have a verbal plan. Having a written plan over a verbal plan provides additional safeguards, so all employees know the same responses to emergencies, and it can be referenced during an actual emergency.

An internal safety audit program is used by an organization to evaluate the effectiveness of the procedures and processes used to meet OHS legislative and other statutory administrative requirements.

An internal safety audit program is used by an organization to evaluate the effectiveness of the procedures and processes used to meet OHS legislative and other statutory administrative requirements.

Musculoskeletal disorders (MSDs), these are injuries to the skeleton, muscles, cartilage, tendons, ligaments and joints that support and bind tissues and organs together so the body can move and sustain itself.

Musculoskeletal disorders (MSDs), these are injuries to the skeleton, muscles, cartilage, tendons, ligaments and joints that support and bind tissues and organs together so the body can move and sustain itself.

With nearly 100,000 injuries or fatalities due to forklift accidents in the U.S. each year, proper training is a critical part of forklift safety. Forklifts present a unique workplace hazard for many reasons: they weigh at least double the weight of the average car, they carry very heavy loads at heights, they work in areas close to people and other equipment, and they steer from the rear. It’s estimated that proper training can help prevent 70% of forklift accidents. To ensure that all operators are sufficiently skilled and knowledgeable, training standards are set by the Occupational Health and Safety Administration (OSHA) in the U.S. and the Canadian Standards Association (CSA) in Canada.

With nearly 100,000 injuries or fatalities due to forklift accidents in the U.S. each year, proper training is a critical part of forklift safety. Forklifts present a unique workplace hazard for many reasons: they weigh at least double the weight of the average car, they carry very heavy loads at heights, they work in areas close to people and other equipment, and they steer from the rear. It’s estimated that proper training can help prevent 70% of forklift accidents. To ensure that all operators are sufficiently skilled and knowledgeable, training standards are set by the Occupational Health and Safety Administration (OSHA) in the U.S. and the Canadian Standards Association (CSA) in Canada.

An accident analysis report should be conducted for every accident, but also conducting an accident analysis for a near miss will create a safer workplace. It may seem excessive to treat every near miss as a full accident, but a near miss is just an accident where someone didn’t happen, this time.

An accident analysis report should be conducted for every accident, but also conducting an accident analysis for a near miss will create a safer workplace. It may seem excessive to treat every near miss as a full accident, but a near miss is just an accident where someone didn’t happen, this time. More incidents and observations mean more data to analyze

More incidents and observations mean more data to analyze